Industry analysts and copper rotor motor supporters suggest that the test results from these. Vehicle powertrain electrification has gotten a lot of attention in the last few years particularly from major automakers and other original equipment manufacturers oems seeking to reduce fuel consumption and emissions.

Remy International Riding The Waves Of Innovation Copper

Copper Rotor For Hermetic Motors Buy Hermetic Motor Electric Motor Rotor Copper Rotor Product On Alibaba Com

Copper Delivers Energy Power And Speed

In fact the manufacturer is reportedly charging roughly the same price for these copper rotor motors as for their aluminum rotor counterparts.

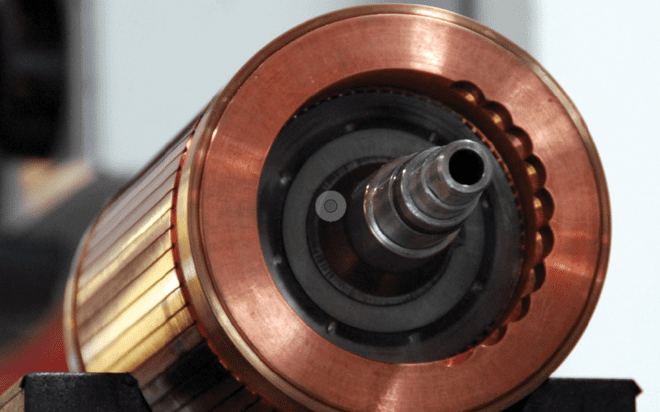

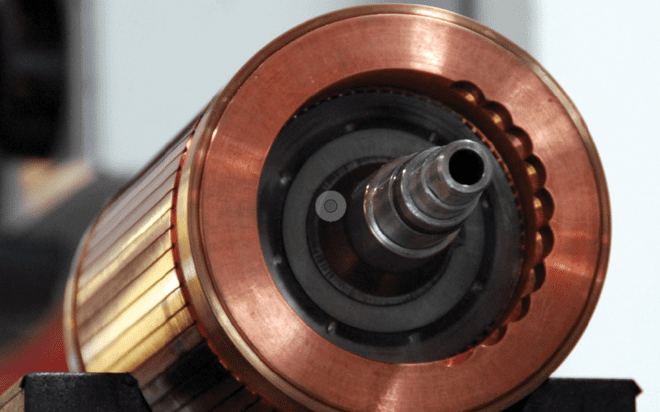

Induction motor copper rotor. In operation the non rotating stator winding is connected to an alternating current power source. The alternating current in the stator produces a rotating magnetic field. Shortening the motor eliminates some of the.

A squirrel cage rotor is the rotating part of the common squirrel cage induction motorit consists of a cylinder of steel laminations with aluminum or copper conductors embedded in its surface. As automotive manufacturers view their options for reducing fuel consumption and emissions electrical propulsion becomes more attractive. Copper improves the performance of induction motors innovative technology benefits hybrid and plug in hybrid vehicles.

Using a copper rotor while maintaining the motor efficiency. One alternative to rare earths in traction motors m. Copper rotor motor english.

Copper rotor induction motors to power evs copper is a viable alternative to expensive rare earths. Preliminary testing on the copper rotor motors have confirmed the expected efficiency gains. In larger induction motors copper or copper alloy bars are used to fabricate the rotor cage winding.

The most common type of i nduction motor has a squirrel cage rotor in which aluminum conductors or bars. The use of copper for the conductor bars and end rings of induction motors in place of aluminum results in attractive improvements in motor energy efficiency. Historically internal permanent magnet ipm motors have been a popular motor design.

Until recently die cast motor rotors were universally produced using aluminum because rotor fabrication by aluminum pressure die casting was an established practice. The motors will use copper rather than aluminum in the motors rotor a seemingly elementary change yet one that can lead to a 20 reduction in electrical losses in the motor. By bob chabot contributing editor.

Copper rotor induction motors. Ac induction motor volts per hertz control with speed closed loop. This is because the higher efficiency of the copper rotor allows the overall length of the rotor and motor to be decreased while still matching the performance of a motor utilizing an aluminium rotor.

Burwell north american director of technology development and transfer for the international copper association 2012. The copper development association cda is a member of an industry government consortium that is currently developing the improved motors.

Die Cast Copper Rotors For Electric Mobility Favi

Cast Copper Induction Motor Drives

Die Casting Copper Rotor Technology Solar Impulse

Electromobility Components Wieland Werke Ag En

Recent Advances In Electric Machine Design And Operation

New Motor Technologies Boost System Efficiency

Squirrel Cage Induction Motor Working Principle Applications

Pmac Vs Induction Motor For Model 3 Page 25 Tesla Motors

Novel Manufacturing Technologies For High Power Induction

Copper Rotor Induction Motor The Better Solution To Power

Aceturbo

Copper And Electricity Efficient Motors

Comments

Post a Comment